Juho Valkola

Positive environmental impact and productivity gains from factory prefabrication are examples of arguments used for timber multi-storey construction (TMC). However, relatively few TMC projects have been completed in Finland due to costliness and risks. Why is TMC costly and risky then, and how to diminish these characteristics?

This article was first published in Finnish.

First, there are technical challenges like soundproofing, durability, and restraining structural deflections. Commercial solutions like decoupled structural layers with heavy inert sheathing and prestressing (Asdrubali ym. 2017) can often overcome those. But the hindrance of TMC overall is its immaturity. Still, instead of only expecting TMC to mature and evolve until it fits to existing construction conventions, it would be wise if the usual construction practices were also proactively adapted to fit the processes of TMC. With this two-pronged approach TMC could become broadly commercially viable sooner and offer a competitive advantage to ambitious businesses.

This is one implication drawn from the findings of my master’s thesis “Business problems in timber multi-storey construction ecosystems: reasons to reorganize?”. I studied the applicability of residential TMC in various Finnish main contractor companies through 23 interviews with directors and managers, who totalled over 500 years of expertise on the subject. In addition to inquiring about timber specifically, their reasonings for choosing between different reinforced concrete (RC) frame types were generalized to TMC in the thesis. As recognized in prior research (Hemström ym. 2016), the interviews confirmed that main contractors play a key role in determining a frame type for a building. In their choice however, main contractors must account for other parties as well. Dealing with problems of fitting people together and technologies together, like the different parties involved with TMC, is what learnings from my Organization Design and Leadership major in the master’s programme of Industrial Engineering and Management at Aalto University should allow.

Findings from the interviews: roles and problems in TMC adoption

Ultimately, ten business problems for residential TMC adoption for main contractors were recognized from the interviews:

- Markup Problem: Both timber building-element producers and main contractors markup timber frames higher than in RC construction due to prefabrication, risks, and incompatible operating models.

- Regulation Problem: The public body in Finland supports TMC administratively, but the building code and municipal officials seem to be rooted to RC construction and therefore may be net impediments to TMC adoption.

- Demand fluctuation problem: It is hard for main contractors to use and manage in-house field-workforce and element production capacity due to large inherent fluctuations in local construction volumes.

- Human Resource Problem: Immature TMC is disadvantaged by a strong reliance on obtainability of experienced project personnel when main contractor chooses a building frame type for a project.

- Element Availability Problem: Varying availability of building elements due to distances and market fluctuations often make or break commercial viability of elementized construction, including TMC.

- Incompatibility Problem: Intense collaboration with timber element producers is incompatible with usual construction industry companies’ operating models meant for commoditized means of production.

- Innovation Problem: Main contractors’ competitiveness often rests on dependability, which makes radical innovations in construction methods counterproductive for them.

- Risk Problem: Uncertainty stemming from lack of experience in using timber or hybrid frames and from doubts about their performance have a vast impact on construction projects’ risk premiums.

- Element Typology Problem: Limitations in forms and features of building elements decrease the commercial viability of prefabrication.

- Modifiability Problem: Impossibility (or extra costs) of late modification of elements with a high degree of prefabrication make them unusable in most builder vendor projects.

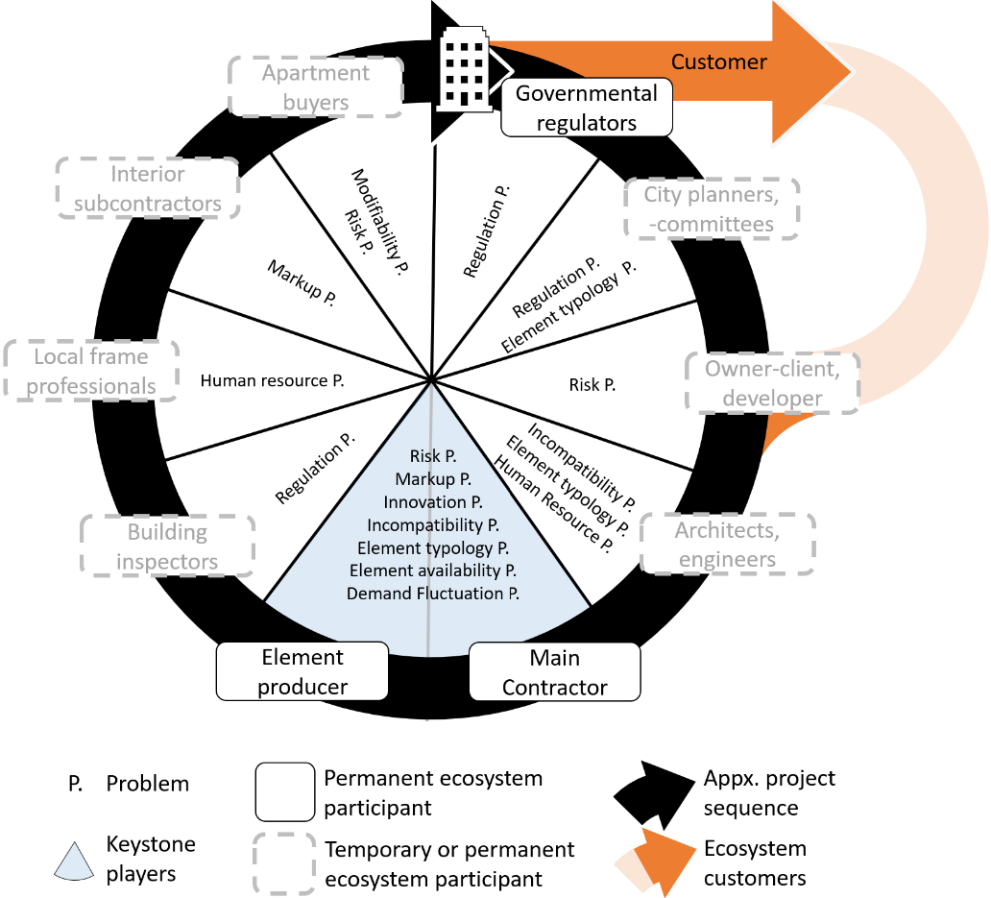

A TMC ecosystem overview figure below relates the ten problems to project participants who influence the frame-type choice. Most problems connect the main contractor and the timber building element producer. Moreover, substantial resources are required for project contributions from these two parties, which likely requires mutual adaptation to TMC more so than for other parties. This suggests they are the two “keystone roles” (Adner 2016) in a TMC ecosystem. Governmental regulators are particularly important TMC ecosystem participants because of the wide-ranging impact of building codes.

Considering the ten problems altogether clarifies some of the reasons why timber frames are often more expensive than RC frames. As commonly recognized, one part of it comes from higher direct costs from lack of routines and higher complexity of TMC compared to RC (Kesik & Rosemary 2021). Indirect effects to costs are also significant. The Regulation Problem makes TMC more complex, perhaps partly needlessly. Inefficiencies in the companies’ operating models manifest as the Markup Problem. This problem could be solved by performing element production and main contracting in one integrated company. The Demand Fluctuation Problem is an obstacle for this vertical integration, though: only a few companies in Finland have enough resources to let them execute enough TMC projects to cover the fixed costs of timber element production by themselves.

The immaturity of TMC combined with demand fluctuation makes TMC projects too few and irregular to incentivize existing professional frame crews to specialize in TMC and help solve the Human Resource Problem. Finer division of labour that prefabrication allows was described by interviewees to decrease these specialization costs. Unfortunately, prefabrication poorly fits main contractors’ operations, as per the Incompatibility Problem. Furthermore, the few existing timber element producers offer inequivalent products, prompting action also on the Element Availability problem.

The Innovation and Risk Problems are other obstacles to investing in TMC. Only TMC projects where the risks are compensated seem to be taken up in Finland, like in simpler, smaller buildings and when timber frames are required by municipalities. Product development and testing could ascertain the robustness of TMC and mitigate the Risk Problem. Similarly, solving the Element Typology and Modifiability Problems starts from technical development, but also requires an ecosystem able to deliver the enhanced product cost-effectively.

Implications for accelerating TMC adoption

The problems imply that existing companies likely either lack motivation, capabilities, or resources to vertically integrate main contracting and element production. Most interviewees suggested, like others have before (Jones ym. 2016), that TMC ecosystem would mature and become cost-competitive with RC through a widening supplier base for timber elements, and product harmonization between the suppliers. This will likely happen eventually, but proactive development of a new TMC ecosystem to solve the ten problems would likely accelerate the adoption of TMC.

Motivated by the possibility of taking the lead in TMC, long-term partnering between an element producer(s) and a main contractor(s) could enable the new ecosystem. A new joint venture, or accommodating the entire operations of the separate companies, or other long-term collaboration between the keystones is required for tackling the ten problems. Benefits of additional recurring revenue, for example, could attract other parties to the collaborative ecosystem as well. A co-operative strategy requires removing operational redundancies and imbalances in rewards and responsibilities between the keystones. A degree of exclusivity for each other’s offerings should be agreed on for mutual enticement. Still, before reaching a large enough scale, the players may also need to act outside the ecosystem to balance solving the Demand Fluctuation- and Element Availability Problems. Large companies would reach a sufficient scale for TMC faster but may find it harder to adapt to a new ecosystem than smaller companies.

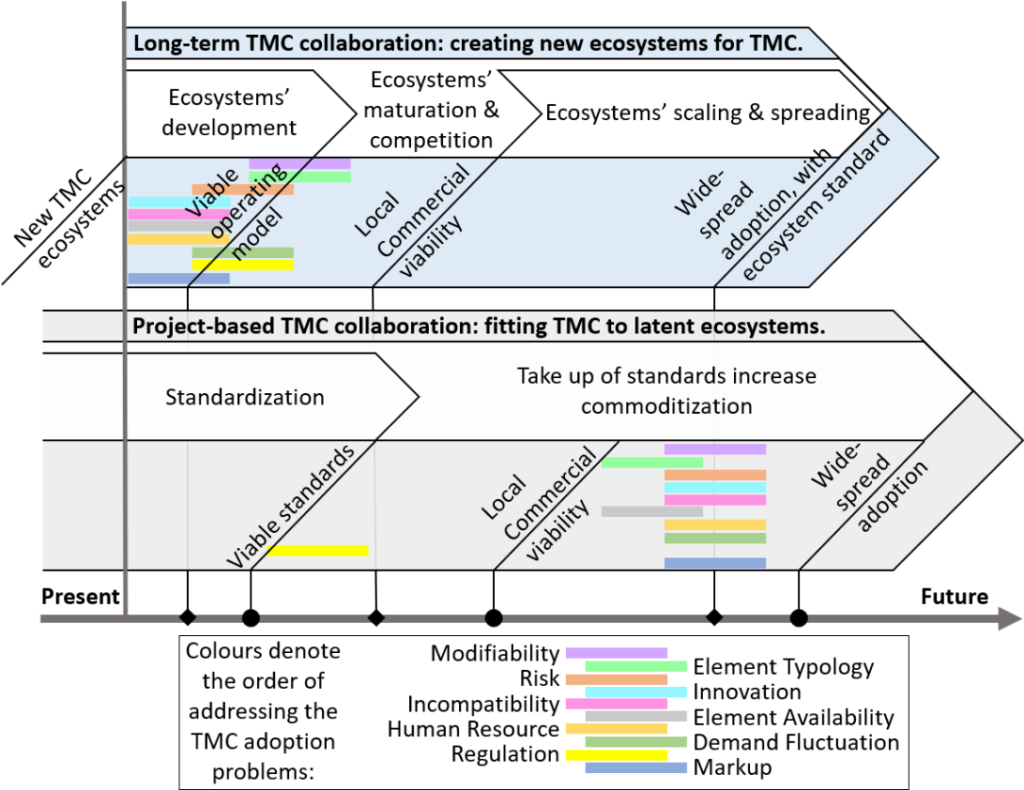

As visualized in the above figure, the proactive course of development for new TMC ecosystems would invert the approach commonly foretold. Instead of aiming for an established industry to reach commercial viability, the business should first be fundamentally viable to then act as a seed for a newly established industry. Practically speaking, instead of relying on industry-wide standardization and gradual growth of timber element supply and of TMC experience of (sub)contractors to solve the ten problems, the proactive approach would first tackle the problems and gain a competitive advantage on a smaller scale. Then, companies’ growth and new participants in a successful ecosystem would eventually lead to wide-spread commercial viability of the TMC ecosystem’s standards. The proactive route would arguably be faster, thanks to competitive pressures against RC and other TMC ecosystems. If the new ecosystems can also capitalize on the advantages in prefabrication, precision, quality, and aesthetics that timber provides, there will be strong reasons for many companies to participate.

From the point of view of ecosystems as well as organization design and leadership provided by a background in Industrial Engineering and Management, the thesis supplemented the previous research and public knowledge on the adoption challenges that TMC face in the construction industry. By providing details and practical examples drawn from the interviews, this study highlights organizational and collaboration problems which may have been overshadowed by technical challenges in previous research. It will be up to interested construction industry parties, such as main contractors and regulators, to further consider these issues if they wish to improve the rate of TMC adoption. In any case, operational incompatibility must be solved by collaboration, even if the end state is a TMC ecosystem the like of RC element ecosystems with commoditized products. Why not take the future into the companies’ own hands and collaborate both in the beginning and in the end?

For the whitepaper version and more scholarly sources, the full study is available at: https://aaltodoc.aalto.fi/bitstream/handle/123456789/116333/master_Valkola_Juho_2022.pdf?sequence=2&isAllowed=y

Sources

Adner, R. 2016. Ecosystem as Structure. Journal of Management, 43, 39–58. available: doi:10.1177/0149206316678451. Cited 23.9.2022.

Asdrubali, F., Ferracuti, B., Lombardi, L., Guattari, C., Evangelisti, L., & Grazieschi, G. 2017. A review of structural, thermo-physical, acoustical, and environmental properties of wooden materials for building applications. Building and Environment, 114, 307–332. Available: doi:10.1016/j.buildenv.2016.12.033. Cited 23.9.2022.

Hemström, K., Gustavsson, L., & Mahapatra, K. 2016. The sociotechnical regime and Swedish contractor perceptions of structural frames. Construction Management and Economics, 35, 184–195. Available: doi:10.1080/01446193.2016.1245428. Cited 23.9.2022.

Jones, K., Stegemann, J., Sykes, J., & Winslow, P. 2016. Adoption of unconventional approaches in construction: The case of cross-laminated timber. Construction and Building Materials, 125, 690–702. Available: doi:10.1016/j.conbuildmat.2016.08.088. Cited 23.9.2022.

Kesik, T., & Rosemary, M. 2021. Mass Timber Building Science Primer. Mass Timber Institute, University of Toronto. Available: https://academic.daniels.utoronto.ca/masstimberinstitute/wp-content/uploads/sites/5/2021/04/MTBSP-Version1.0-04-13-21.pdf

Valkola, J. 2022. Business problems in timber multi-storey construction ecosystems: reasons to reorganize? Espoo. Aalto Yliopisto. Available: https://aaltodoc.aalto.fi/bitstream/handle/123456789/116333/master_Valkola_Juho_2022.pdf?sequence=2&isAllowed=. Cited 23.9.2022.

Juho Valkola, M.Sc

RDI-specialist

Centria Research and Development

p. 040 519 4241

www.linkedin.com/in/juho-valkola-944176114